Need any help or advice?+44 (0)1782 450300

Downloads (7)

This is a chemical product. Before storage or use you must download and read the accompanying safety and technical datasheets.

| Safety Datasheet (SDS) - EN | ||

| Safety Datasheet (SDS) - NL | ||

| Technical Datasheet (TDS) | ||

| Resin Flowers Kit Handbook | ||

| Less Resin River Table Handbook | ||

| Forged Carbon River Table Handbook | ||

| How To Make a Resin River Table Handbook |

Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 50 Clear Epoxy Casting Resin - 500g

- GlassCast®

- 4.5/5 Average rating

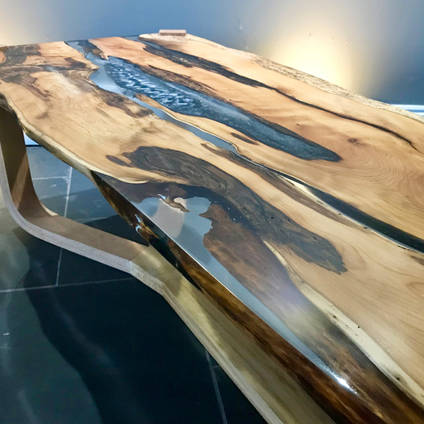

GlassCast 50 is a crystal clear, two-part epoxy resin designed deep section castings for projects such as wood-turning blanks, furniture like resin river tables and large castings. The recommended pour thickness for GlassCast 50 is up to 50mm deep into silicone or 25mm into wood.

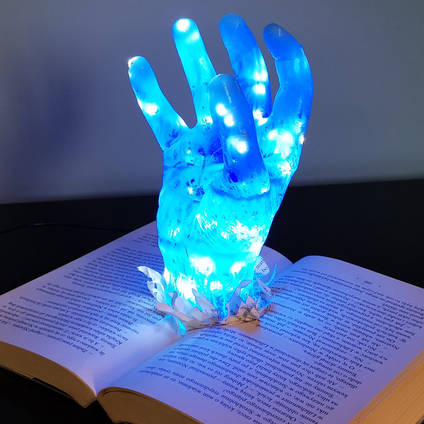

GlassCast 50 can be left clear or pigmented with a wide range of pigments and metallic effects and is our recommended resin for furniture, figurines, encapsulations, large scale blanks for turning and more. It can be layered for greater depth castings.

Sold as a kit, including resin and hardener. Available in 500g, 1kg, 5kg, 15kg and 30kg kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 20 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

GlassCast 50 is the professional's choice for a water-clear, UV resistant epoxy casting resin developed specifically to meet the demands of thick section casting including river tables and other furniture, pen blanks, micarta and wood turning.

Its slow-curing formulation allows it to be poured in depths of up to 50mm (25mm into wood) per layer without overheating.

GlassCast 50 Recommended Uses

- River tables (any total thickness, 25mm per pour)

- Knot/hole filling in wood (with or without pigments or effects)

- Clear casting (larger jewellery pieces, figurines, paperweights)

- Wood turning items like bowls and Pen blanks

GlassCast 50 Advantages

- Incredibly clear - no epoxy beats it for clarity

- Highly UV stable - GlassCast 50 is best-in-class

- Natural air bubble release - almost zero trapped air without degassing

- Highly machinable - great for turning, shaping and polishing

- 12 month shelf life

- 100% solids - zero shrinkage

- No odour - VOC free

Intended for Professional/Industrial Use

GlassCast 50 is a professional-grade product intended for professional use only. Under EU/UK CLP & REACH regulations, it should only be used by industrial/professional users. Before purchase, users must read the product's safety datasheet and ensure that safety precautions are understood and followed.

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (recommended) | 25°C (maximum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 80 mins | 60 mins | 40 mins |

| Maximum Pour Depth into a thin walled mould (silicone/plastic) | 50mm | 40mm | 30mm |

| Maximum Pour Depth into wood or an insulating mould | 25mm | 25mm | 18mm |

| Initial Cure | 96 hrs | 72 hrs | 48 hrs |

Further Information

Casting, Not Coating

GlassCast 50 has been formulated as a casting resin and not a coating resin meaning that it is water-clear even in very thick section. It doesn't, however, self-level to quite the perfectly flat, glossy finish of our GlassCast 3 coating resin and usually requires a flat and polish if a perfect finish is required on the open face.

Outdoor Use

Despite the very good advanced 'UV' resistant formulation of our Glass Cast resins, we don't suggest using the GlassCast range of resins for permanent, outdoor applications. This is down to epoxy chemistry meaning that eventually, over time, depending on UV exposure, environmental conditions etc, the resins will always eventually yellow in outdoor conditions. How visible this is depends on factors such as the underlying colour and conditions experienced.

How to Use

GlassCast 50 has been developed for professional users to produce the best results possible. It is not a 'craft' product and not intended for children or home users. Before purchase, storage or use you must read the safety and technical data. Having said that, GlassCast 50 is easy-to-use and delivers fantastic results under a wide range of conditions.

GlassCast 50 is sold as a kit which includes both the resin and hardener in their correct ratios. Take a look at our resin calculator to work out how much GlassCast you'll need for your project. The resin and hardener are mixed together at a ratio of two parts resin to one part hardener by volume. Because GlassCast 50 is designed for thicker castings, it needs to cure more slowly than other GlassCast resins and will take around 48hrs to cure.

Always download the Technical Datasheet from the 'Downloads' tab for full details on correct measuring, mixing and use of the product.

Getting More Creative - Pigments, Tints and Metallics

Although GlassCast 50 is often used completely clear it is also compatible with our complete range of tints, solid-colour pigments and metallic-effect powders. Many other colours and powders can be added too but be sure to conduct a test to ensure compatibility.

- Metallic effect SHIMR powders for swirling, sparkling colour

- CULR epoxy colour pigments for see-through to opaque in a wide range of colours

- Pinata alcohol inks for vibrant, translucent colour

GlassCast 50 is the professional's choice for a water-clear, UV resistant epoxy casting resin developed specifically to meet the demands of thick section casting including river tables and other furniture, pen blanks, micarta and wood turning.

Its slow-curing formulation allows it to be poured in depths of up to 50mm (25mm into wood) per layer without overheating.

GlassCast 50 Recommended Uses

- River tables (any total thickness, 25mm per pour)

- Knot/hole filling in wood (with or without pigments or effects)

- Clear casting (larger jewellery pieces, figurines, paperweights)

- Wood turning items like bowls and Pen blanks

GlassCast 50 Advantages

- Incredibly clear - no epoxy beats it for clarity

- Highly UV stable - GlassCast 50 is best-in-class

- Natural air bubble release - almost zero trapped air without degassing

- Highly machinable - great for turning, shaping and polishing

- 12 month shelf life

- 100% solids - zero shrinkage

- No odour - VOC free

Intended for Professional/Industrial Use

GlassCast 50 is a professional-grade product intended for professional use only. Under EU/UK CLP & REACH regulations, it should only be used by industrial/professional users. Before purchase, users must read the product's safety datasheet and ensure that safety precautions are understood and followed.

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (recommended) | 25°C (maximum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 80 mins | 60 mins | 40 mins |

| Maximum Pour Depth into a thin walled mould (silicone/plastic) | 50mm | 40mm | 30mm |

| Maximum Pour Depth into wood or an insulating mould | 25mm | 25mm | 18mm |

| Initial Cure | 96 hrs | 72 hrs | 48 hrs |

Further Information

Casting, Not Coating

GlassCast 50 has been formulated as a casting resin and not a coating resin meaning that it is water-clear even in very thick section. It doesn't, however, self-level to quite the perfectly flat, glossy finish of our GlassCast 3 coating resin and usually requires a flat and polish if a perfect finish is required on the open face.

Outdoor Use

Despite the very good advanced 'UV' resistant formulation of our Glass Cast resins, we don't suggest using the GlassCast range of resins for permanent, outdoor applications. This is down to epoxy chemistry meaning that eventually, over time, depending on UV exposure, environmental conditions etc, the resins will always eventually yellow in outdoor conditions. How visible this is depends on factors such as the underlying colour and conditions experienced.

How to Use

GlassCast 50 has been developed for professional users to produce the best results possible. It is not a 'craft' product and not intended for children or home users. Before purchase, storage or use you must read the safety and technical data. Having said that, GlassCast 50 is easy-to-use and delivers fantastic results under a wide range of conditions.

GlassCast 50 is sold as a kit which includes both the resin and hardener in their correct ratios. Take a look at our resin calculator to work out how much GlassCast you'll need for your project. The resin and hardener are mixed together at a ratio of two parts resin to one part hardener by volume. Because GlassCast 50 is designed for thicker castings, it needs to cure more slowly than other GlassCast resins and will take around 48hrs to cure.

Always download the Technical Datasheet from the 'Downloads' tab for full details on correct measuring, mixing and use of the product.

Getting More Creative - Pigments, Tints and Metallics

Although GlassCast 50 is often used completely clear it is also compatible with our complete range of tints, solid-colour pigments and metallic-effect powders. Many other colours and powders can be added too but be sure to conduct a test to ensure compatibility.

- Metallic effect SHIMR powders for swirling, sparkling colour

- CULR epoxy colour pigments for see-through to opaque in a wide range of colours

- Pinata alcohol inks for vibrant, translucent colour

Downloads (7)

This is a chemical product. Before storage or use you must download and read the accompanying safety and technical datasheets.

| Safety Datasheet (SDS) - EN | ||

| Safety Datasheet (SDS) - NL | ||

| Technical Datasheet (TDS) | ||

| Resin Flowers Kit Handbook | ||

| Less Resin River Table Handbook | ||

| Forged Carbon River Table Handbook | ||

| How To Make a Resin River Table Handbook |

We would usually recommend allowing the resin to cure for at least 48 hours before trying to machine it. You will find that the resin machines differently as it continues to fully harden over about a 7 day period. Some turners prefer to do the main shaping work quite early in the cure when the resin is softer and cuts more easily (you'll see the swarf coming off in longer, more pliable peels), but for final finishing (sanding and polishing) the harder and more fully cured the resin is the better; it really doesn't polish well at all until it's really hard after 2-3 days.

Although the first part of the cure is the most critical time, it's really still quite important to maintain the ambient temperature for as long as you can into the cure of the resin. For the GlassCast 50, at 20C this really means 48hrs. If you don't maintain the temperature then what will certainly happen is that the cure itself will take longer; for example, at 10C (not that we suggest it!) the cure time would double from 48hrs (2 days) to 96hrs (4 days). If part of the cure was at the lower temperature then the additional cure time would be somewhere between the two. However, there is more to it than just cure time; if the temperature cycles too much and the cure takes too long then the resin may start to absorb moisture out of the air which can affect the clarity and quality of the cure. So, to cut a long story short - try to maintain the temperature for the 48hrs!

Any mild soap and detergents will be fine for cleaning GlassCast Resin. Try to avoid strong acids or bases or neat cleaning products as it is possible they may dull the surface finish.

The GlassCast range of products are not designed for permanent outdoor use. Although the GlassCast resins have a very high level of UV resistance, the very high levels of UV exposure and the variety of inclement weather and environmental conditions experienced mean that the resin would degrade if permanently used outdoors.

Certainly, we can sell the resin and hardener separately if you need extra of either one one its own. Although not listed on the website we can do this over the phone or you can email us and we can send you an invoice with the correct amounts on it. The hardener for each of the GlassCast products is unique for that product. Using hardeners from other resin systems will cause serious curing issues or it may not cure at all.

Hi Nicole, this would slightly depend on how you'll be making up that total depth. Generally speaking, flower preservation castings are done in at least 2 pours often more. At the very least, the first pour is usually used to provide a clear 'shelf' on which to position the flow so that it appears suspended in the final casting.

If you're doing multiple pours on a casting that will be a total of 7cm thick then it will probably mean that no single pour exceeds the 50mm maximum (per pour) for GlassCast 50 (when pouring into a mould) and so you could use GlassCast 50.

If you wanted to do the whole depth (50mm or more) in a single pour however then you would need to choose the GlassCast 50 PLUS. 50 PLUS allows you to cast up to 100mm (into a mould) in a single pour with a lower risk of the resin over-heating during its cure. This makes it great for big/deep castings and would make it a good choice for 50-70mm flower preservations but the trade off is that it does mean that it takes a lot longer to cure; around 7 days compared to 48hrs for GlassCast 50.

Yes you can. Once the 10/150 surface has cured to a B stage, you can use GlassCast 3 directly on top. Alternatively if the surface has fully cured, key it with 120 grit sand paper and thoroughly clean prior to pouring the resin. To get a nice smooth finish, you would need approximately 2kg per square meter to ensure there is enough resin for it to self level evenly. GlassCast 3 used in this way will provide a high gloss and smooth finish that does not need further polishing.

Unfortunately the GlassCast range of resins are NOT designed to be thinned in use.

The GlassCast resins are not designed to be used in such an environment with constant exposure to water, let alone a saline solution. We don't have any information on how long the resin would last in these conditions unfortunately.

Hi Polly, yes, absolutely. Although GlassCast 50 is most often used for slightly larger scale projects such as wood turning and river tables, it can also be used for jewellery too. The only difference between GlassCast 10, which is our resin that we normally suggest for jewellery, and GlassCast 50 is the speed that they cure at. GlassCast 50 cures slower (around 48hrs) compared to GlassCast 10 (around 24hrs) which means that GlassCast 50 can be used to cast larger, thicker pieces, without the resin over heating. If you use GlassCast 50 to make smaller pieces then they will just take a little longer to cure than they would if you used GlassCast 10.

If you haven't already purchased the resin and are deciding which to buy for your jewellery work then, unless you're making particularly large pieces, then GlassCast 10 is likely to still be the best choice for resin jewellery, just because it cures that bit aster and so you're not waiting as long to de-mould.

Hi Jess, the short answer would be no, we wouldn't recommend GlassCast 50 for such a chunky casting in a single pour, but there are ways you could do it.

It's all to do with preventing the resin from over-heating during the cure. Generally we state a maximum thickness of 50mm (2") for GlassCast when you're casting into a conventional mould (rather than into an insulating material, such as wood - as in the case of a river table, for example). However, since you only need a little more thickness (2.5" rather than 2"), if you put some measures in place to take the heat away from the reaction, such as a strong fan blowing over the whole mould, and work in cooler conditions (15C would be ideal) then you would be able to increase the thickness that you can cast without overheating and be able to do your rose casting in one go.

HDPE is a very chemically inert low energy plastic and as such, in a similar fashion to polypropylene, nylon and PVC, resins will not stick to HDPE.

GlassCast 50 has a maximum working temperature of 55 °C which is much lower than the radiated heat given off by some fireplaces. As such we would not recommend keeping it too close to a fireplace or fire to avoid damaging the resin.

Nonetheless, you should avoid breathing in any odour/vapour in close proximity (i.e. smelling the containers) and of course if you may make your own decision to wear a vapour mask.

Yes, once the GlassCast has fully cured, you should be able to paint over the top no problem but it will depend on the type of paint that you're using. Cured GlassCast is essentially a plastic so you're likely to need to use a two-pack paint like a polyurethane or an acrylic to get a really good bond. We would certainly recommend 'keying' the GlassCast with abrasive paper and then testing a small area first to check the quality of the bond.

Although you could use GlassCast 50 to make a decorative ashtray problem, heat from a cigarette butt would degrade and damage the resin surface over time meaning we would not recommend it for functional use.

...I'm looking for clear resin for coasters and tables which can hold hot plate or mug.

The maximum working temperature for GlassCast 50 is 55°C. GlassCast 50 could be marked by hot objects such as very hot drinks (think fresh black coffee, no saucer). To improve the heat resistance of your GlassCast surface, an elevated temperature post-cure should be undertaken. Even with the post-cure we would recommend being careful about placing down hot cups and items, ideally allowing them to cool first or use a saucer just to be on the safe side.

GlassCast 50 is ideal for larger pen blanks where it's clarity and ability to be poured up to 50mm is ideal. Once cured for a minimum of 48 hours, the pen blank will be ready to machine and turn.

As long as you reseal the bottles promptly after use and store them in accordance with the datasheet, then we would expect you to still achieve the full 12 months shelf life.

Yes you can layer the resin in that way. The ideal method is to pour the second and any subsequent layers when the first layer has become firm but is still tacky. At this stage no further preparation is needed and you are likely to get an almost invisible join line.

If you need to wait until after the first layer has fully cured, then the resin will need a key with sand paper and a thorough clean before pouring the next layer.

GlassCast will stick to many surfaces including stone and concrete. Where surfaces are smooth, it is recommended to key the surface to aid maximising adhesion.

It's worth noting that if you want a resin to 'coat' materials like stone or concrete then the GlassCast 3 Coating Resin would be a better choice. GlassCast 50 is designed for very thick section casting (up to 50mm) but would require polishing on the open surface to achieve the perfect flat gloss finish of GlassCast 3.

Yes, GlassCast 50 can be used to cover the top of the project as well as the deeper sections. The cured surface finish of GlassCast 50 is not quite as perfect as the GlassCast 3 (which is designed specially as a 'coating resin') but for most applications you would probably be perfectly happy with the surface finish straight from the GlassCast 50 pour. If you do need absolute perfection then you can always flat and polish the surface, which is quite easily done with GlassCast 10 and 50.

Yes GlassCast 3 can be used in this way. If you are making a river table and want a thin layer of resin right over the top of the wood as well, then using GlassCast 3 in this way over the top of the GlassCast 50 will give a smoother finish on the surface.

After allowing a minimum of 48 hours curing time, the GlassCast 50 can be machined, cut, sanded and shaped no problem. Once finished you will be able to polish the resin back to a very high gloss.

There are no known issues with encapsulating LED's in resin in terms of curing or using the resin. The only area of concern is ensuring the LED cluster is fully working before pouring the resin and also long term maintenance - any failed LED's would be unable to be replaced.

You can certainly use tints and pigments when working with LED's. The way the LED diffuses the light may effect how the overall piece looks.

This usually occurs when you're doing particularly deep pours and generally when the mixing has been quite vigorous and resulted in a lot of smaller air bubble entrapment. Smaller bubbles are more difficult for the resin to release because they have less buoyancy compared to their drag (less volume as a ratio to their surface area).

To reduce the air entrapment in the first place the solution is to mix more slowly and purposefully, making ever effort you can not to 'whip' air into the resin. Also, make sure that the resin is at a starting temperature of 20°C when you mix it. If the resin is cooler then it will be thicker and more prone to air entrapment when mixing. To help to eliminate the air that does get mixed into the resin it's helpful to pour the resin a bit at a time, using a hair dryer or heat gun gently each time you add some more resin. This way the air bubbles don't need to rise as far and the affect of the heat gun can penetrate each shallower pour of resin more easily. This isn't the same as making up the depth in multiple pours (allowing the resin to cure between each pour). What I'm describing is just pouring out maybe 5mm, then gently hair-dryer, watch the bubbles pop, pour another 5mm and keep going.

The risk from deep pours (deeper than 25mm) is that the resin could exotherm (overheat) during the cure which can cause it to crack, distort and discolour. If the resin doesn't get into this overheating spiral and stays relatively cool during the cure then there is no disadvantage to deeper pours. We have one customer who regularly manages 50mm depth in a single pour by positioning big fans blowing air over the table to keep the resin temperature down.

The exact grade of abrasive you should use to key a fully cured previous pour of resin isn't too critical but you should use something reasonably coarse; we would normally use a 120 or 240 grit. And yes, worry not! The next pour of resin will fill in all the scratches and there shouldn't be any evidence that they were ever there.

Small defects in the Glasscast finish can be cut/drilled out and then refilled to repair the damage. However it is essential that you thoroughly clean the area being repaired before you refill with resin to avoid any dust or dirt being trapped.

Yes you can clean the surface in that way or by using pre-made IPA wipes. Bear in mind, you will still need to key the surface with 120 grit sand paper before cleaning to ensure the best bond between the resin layers.

GlassCast 50 is very much a rigid resin once fully cured and as such would not be considered to have any noticeable flexibility.

Good question. It's hard to say for sure because household clingfilm can actually be made from a number of different types of plastic and therefore have different release properties. In the past we have seen GlassCast release from some clingfilm but on other occassions it seems to have well and truly stuck. Therefore, the only firm advice we can give you would be to test a small area first in order to see if it releases from your clingfilm.

One other option to consider if you're looking for a low cost release material is brown packing tape. Packing tape/parcel tape is almost always made from polypropylene which GlassCast doesn't stick to so you're pretty safe if you cover something in brown parcel tape, rather than clingfilm.

20C is definitely the recommended working temperature but there is a bit of leeway on this. With GlassCast 50 I would suggest that 15C would be the minimum acceptable working temperature.

What you'll find when working at lower temperatures is the that the resin and hardener will both feel thicker than they normally would; this can mean that more air gets mixed in when you mix the resin and hardener together and so it becomes more important to mix carefully to avoid aerating the resin when mixing and also maybe a bit more thorough with the heat-gun or hair dryer when removing bubbles from the poured resin. The other affect you'll see in cooler conditions is that the resin will take longer to cure than we state on our datasheets/tutorials etc although other than a bit more patience, this is not normally an issue.

Just for completeness in the answer, working at temperatures much higher than 20C is more of a worry because of the risk of the resin over-heating during cure. If you do ever find yourself working at higher temperatures then you would need to reduce the maximum casting thickness from 25mm to something more modest.

Yes, you can definitely do this with GlassCast 50 but there would be a couple of things to think about when you do. When casting into a mould (including your sphere mould/container) GlassCast 50 can be used for sections up to a maximum of 50mm thick. It can be tricky to explain but what we mean by 'thickness' is the smallest of the 3 dimensions if you could measure the resin block (or the gap where the resin will be) in all 3 directions (example: width, height, depth). If the resin will be more than 50mm in length, AND width, AND depth at any point then you would need to pour the resin in layers, to avoid it over-heating whilst it cures. If - because of how much space the burl takes up - the resin wouldn't ever exceed 50mm in all 3 dimensions anywhere on the casting then you could do it in one pour.

In terms of then turning down the piece once cured, you'll have no problem. We have lots of beautiful examples of similar pieces in our gallery.

ASK YOUR OWN QUESTION

Customer Product Reviews for GlassCast 50

Perfectly clear, bubble-free resin that produces consistent results. As a premium product, it does suffer with crystallisation, but always returns to water clear after sitting in 60+ degree water for a while. Minimal shrinkage is also a big plus point.

Fantastic product, great at degassing for bubble free castings, good machinability when cutting, turning or shaping/carving.

Great. Super happy. Fast delivery (came next day) and thanks to Charlotte in the office who helped me to find the delivery (at my own house!!

I've been using glass cast 50 since the beginning and have now produced nearly 20 river tables and similar projects. I tested a few other resins in the beginning and settled on glass cast 50 because of the cure speed and bubble free finish. Other resins I tested for river tables were much too slow to cure. One took a week to cure and still felt too soft to machine properly. Great product.

TOP PRODUCT!! have used Glasscast 50 for 3 river tables now, they have all worked perfectly and great technical support from Warren who helped me figure out a problem I was having with tiny air bubbles (was caused by jiffy mixer - dont use one!). Great product, great service.

brilliant product, really happy with the end result, did exactly what it said on the tin. only reason I didn't give 5 stars is because it would have been better if I could buy a 2.5kg kit, the 5 was too big and the 1kg is too small.

No comparisson! Glasscast 50 is the only epoxy resin i will use for my river tables. quality of the product is spot on - bubble free, cures hard, machines great, polishes great. What more can I say? 5 star product.

I have been working with resin for quite a while now, using various resin products, with varied results. After trying GlassCast, I have found a product I'm sticking with. Easy to work with, easy to finish. Night and day from others I have used. Highly recommended.

Highly recommend! Great products supplied via great service. Top quality all round. Will be staying with GlassCast and not even tempted to look elsewhere!

Very good resin, very clear. I use it to top my work but can use normally.

Loving the Glasscast 50! Super clear castings without bubbles. Perfect for woodturning.

Specifically bought glasscast 50 as the reviews were fantastic, followed the guidance to the last detail (had very expensive failures in the past) this still went excothermic at a 35mm pour. Very disappointed

I use a combination of GlassCast 50 for the deep pours I do and GlassCast 3 for finishing and flood coats. I love the products and the service I receive from the team. A score of 5 is not high enough for the quality and service you get from the team!

Never used resin before and after some research and talking to the team they advised GlassCast 50 Clear Epoxy Casting Resin suited my needs and guided me through the process. There are many variables when pouring resin and I found GlassCast 50 easy to use, I would recommended the GlassCast range of resins.

I can always guarantee the standard when using GlassCast, it’s the resin I recommend wholeheartedly and I wouldn’t use any other for my business. Resin art and product creation is vastly growing in popularity, so in an increasingly competitive market, I need that confidence in the quality of materials that I’m using. GlassCast 3 is perfect for my Artworks and home decor pieces, and GlassCast 50 never fails me when it comes to casting and preservation products. My only complaint would be that I’m constantly running out, but thankfully they offer speedy delivery also!

I’m a floral resin artist and would give glasscast 5/5, and more if possible. I use glasscast 10 and glasscast 50 and it’s by far the clearest resin I have found. Very easy to work with and I wouldn’t hesitate in recommending this brand to other floral artists.

GlassCast 50 has been a game changer for me. It's the prefect product to help me create unique functional art , allowing me to use all of the locally sourced trees including there natural defects to make something truly unique.

I have used quite a few different resins but I always seem to always come back to GlassCast Resin. I find it to be a really easy resin to use and cast with. It’s particularly good for crystal clear casts even without the use of a pressure pot (you need to know a few tricks though). I push this resin quite far and pour deeper than the recommended depth and it always copes well and surprises me. It is very competitively priced along with similar resins and cheaper than some of the “big” names in resin/epoxy.

I took the plunge and changed resin company. GlassCast grabbed my attention from the start. Made it really easy to understand which type of resin to use for what job. and I've never looked back! Clear, easy to work with. Minimal bubbles and cures with perfection.

Easy to use resin. It was solid as 24 hours, rock hard at 36 hours. Benefits from a hot water bath before mixing for less bubbles. Crystal clear pour after putting into into a vac chamber to remove bubbles.

Follow the instructions for great results. Very pleased with the Glass Cast 50. Used it for trialing some wood coasters with small items cast in to hollow parts. Followed the instructions and got great results.

Love this stuff, just stir it properly and let sit before pouring. I blowtorch it before I pour. (easier)

Love the GlassCast range for my projects. Highly recommend.

Great casting product. Lovely product to use , easy to measure and little odour . A little more expensive than other brands but I find this the best after trialling others. Good clear finish and excellent quality product to sell .

Fab product, great to use.

Used to set pencils and used for wood turning worked out great. Easy to use and follow instructions.

This resin is fantastic, I have made lots of things with it. Definitely will buy more. Great instructions to follow.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Related Products

Customers Also Bought

Related Products

Customers Also Bought

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.