Need any help or advice?+44 (0)1782 450300

Downloads (4)

This is a chemical product. Before storage or use you must download and read the accompanying safety and technical datasheets.

| Safety Datasheet (SDS) - EN | ||

| Technical Datasheet (TDS) | ||

| The Resin River Table Handbook | ||

| Forged Carbon River Table Handbook |

Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 50 Epoxy Resin for River Tables - 5kg

- GlassCast®

- 4.5/5 Average rating

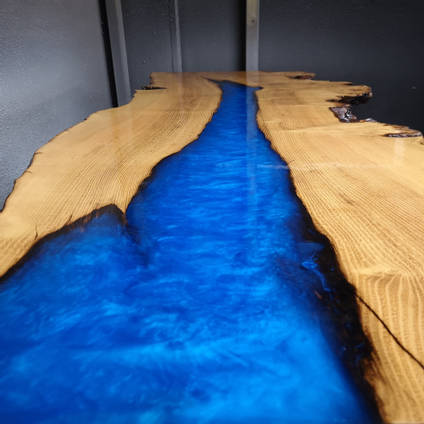

GlassCast 50 was developed specifically with resin river tables in mind and has been the professional's choice in clear epoxy casting resin for many years, offering superb clarity, outstanding non-yellowing properties, optimum cure speed and excellent toughness. GlassCast 50 has a recommended pour thickness of 25mm when being poured next to wood in a river table, but can be layered for greater depths.

GlassCast 50 can be left clear or pigmented in classic translucent blue like the very popular resin river tables or if solid colours or metallics are more your style, our epoxy compatible pigments can be used.

Sold as a kit, including resin and hardener. Available in 500g, 1kg, 5kg, 15kg and 30kg kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 10 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Professional-grade epoxy for resin river tables

GlassCast 50 was developed specifically with professional resin river tables manufacturers in mind, offering superb clarity, outstanding non-yellowing properties, optimum cure speed and excellent toughness.

Intended for Professional/Industrial Use

GlassCast 50 is a professional-grade product intended for professional use only. Under EU/UK CLP & REACH regulations, it should only be used by industrial/professional users. Before purchase, users must read the product's safety datasheet and ensure that safety precautions are understood and followed.

Why choose GlassCast 50 for your river table project?

GlassCast 50 has been the #1 choice for thousands of professional furniture makers, including recognised experts like ManorWood, for more than 6 years; there is no better epoxy resin for projects like river tables.

This water-clear, UV resistant epoxy casting resin has been developed specifically to meet the demands of casting in thick section; especially in contact with live-edge wood. Its advanced formula self-degasses to remove air bubbles whilst its best-in-class UV blockers ensure your river table will still look fantastic for years to come; especially important if you're selling your tables commercially.

- Incredibly clear - No epoxy beats it for clarity

- Unbeatable UV stability - Best-in-class with a 3 year track record

- Natural air bubble release - Almost zero trapped air without degassing

- Highly machinable - Cuts, sands and polishes beautifully with great scratch resistance

- Solvent free - No VOCs, no odour, zero shrinkage

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below. Don't forget your resin will begin to cure as soon as you start to combine the resin and hardener.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 80 mins | 60 mins | 40 mins |

| Maximum Pour Depth into a thin walled mould (silicone/plastic) | 50mm | 40mm | 30mm |

| Maximum Pour Depth into wood or an insulating mould | 25mm | 25mm | 18mm |

| Initial Cure | 96 hrs | 72 hrs | 48 hrs |

Maximum Pouring Depth

GlassCast 50's slow curing formulation allows it to be poured into wood (a highly insulating environment) at depths of up to 25mm per pour. For a typical river table, this usually means pouring in two layers over consecutive days.

Several of our commercial customers, including the very popular Youtube channel ManorWood, do use GlassCast 50 to cast 50mm river tables in a single pour, however - this can only be done by setting up forced cooling (such as fans) over the project and so should only be attempted by expert users.

Tints, Pigments and Effects

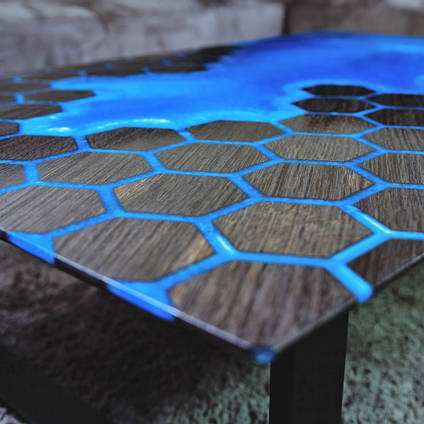

GlassCast 50 is water clear many river tables are made with the resin left perfectly clear, but - if you're looking to give your river table a different look then the options are almost limitless.

The most popular ways to modify the appearance of the resin in a river table are translucent tints, metallic-effect powders and solid colour pigments but if you really want to personalise your river table then just about anything can be added to the resin from pebbles, stones and shells through to photos, keepsakes, poker chips, or even an old pair of jeans!

- Translucent Tints - See through tints can easily be achieved simply by adding a drop or two of our CULR Universal Pigments to your GlassCast 50 resin. This translucent appearance is similar to a stained glass effect and still allows light to pass through the table, enhancing the appearance of depth. CULR pigments are available in a wide range of colours including Indigo Blue for a classic blue river, or Jet Black for a see-through smoked glassed effect.

- Metallic-Effect Powders - Sparkling, brightly coloured metallic effects can be created by adding your choice of metallic SHIMR powders to the resin which is then stirred and agitated to create ripples and swirling patterns.

- Solid Colour Pigments - Opaque, solid colours can be created by adding CULR Universal Pigment to the resin at around 1%. Solid colours, particularly black or white, create bold contrast with the wood and result in more classically elegant furniture.

- Encapsulations - To really put your unique stamp on a river table it is possible to encapsulate just about any objects within the resin, such as pebbles, shells, toys, trainers, badges, even car parts! The only limit is your imagination.

- Glow in the Dark Powders - Photoluminescent powders, often in blue or green but also available in other colours, can be mixed into the resin to create a river that glows in the dark.

Outstanding Technical Support

See the accompanying video tutorials for step-by-step guidance on the successful use of GlassCast 50 for a range of applications, including the classic river table.

For a 'deeper dive', download our Resin River Table Handbook which goes into more detail and covers troubleshooting and alternative methods.

If you still have any questions not covered in the tutorial or guide, just get in touch with our technical team via email, LiveChat or over the phone.

Professional-grade epoxy for resin river tables

GlassCast 50 was developed specifically with professional resin river tables manufacturers in mind, offering superb clarity, outstanding non-yellowing properties, optimum cure speed and excellent toughness.

Intended for Professional/Industrial Use

GlassCast 50 is a professional-grade product intended for professional use only. Under EU/UK CLP & REACH regulations, it should only be used by industrial/professional users. Before purchase, users must read the product's safety datasheet and ensure that safety precautions are understood and followed.

Why choose GlassCast 50 for your river table project?

GlassCast 50 has been the #1 choice for thousands of professional furniture makers, including recognised experts like ManorWood, for more than 6 years; there is no better epoxy resin for projects like river tables.

This water-clear, UV resistant epoxy casting resin has been developed specifically to meet the demands of casting in thick section; especially in contact with live-edge wood. Its advanced formula self-degasses to remove air bubbles whilst its best-in-class UV blockers ensure your river table will still look fantastic for years to come; especially important if you're selling your tables commercially.

- Incredibly clear - No epoxy beats it for clarity

- Unbeatable UV stability - Best-in-class with a 3 year track record

- Natural air bubble release - Almost zero trapped air without degassing

- Highly machinable - Cuts, sands and polishes beautifully with great scratch resistance

- Solvent free - No VOCs, no odour, zero shrinkage

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below. Don't forget your resin will begin to cure as soon as you start to combine the resin and hardener.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 80 mins | 60 mins | 40 mins |

| Maximum Pour Depth into a thin walled mould (silicone/plastic) | 50mm | 40mm | 30mm |

| Maximum Pour Depth into wood or an insulating mould | 25mm | 25mm | 18mm |

| Initial Cure | 96 hrs | 72 hrs | 48 hrs |

Maximum Pouring Depth

GlassCast 50's slow curing formulation allows it to be poured into wood (a highly insulating environment) at depths of up to 25mm per pour. For a typical river table, this usually means pouring in two layers over consecutive days.

Several of our commercial customers, including the very popular Youtube channel ManorWood, do use GlassCast 50 to cast 50mm river tables in a single pour, however - this can only be done by setting up forced cooling (such as fans) over the project and so should only be attempted by expert users.

Tints, Pigments and Effects

GlassCast 50 is water clear many river tables are made with the resin left perfectly clear, but - if you're looking to give your river table a different look then the options are almost limitless.

The most popular ways to modify the appearance of the resin in a river table are translucent tints, metallic-effect powders and solid colour pigments but if you really want to personalise your river table then just about anything can be added to the resin from pebbles, stones and shells through to photos, keepsakes, poker chips, or even an old pair of jeans!

- Translucent Tints - See through tints can easily be achieved simply by adding a drop or two of our CULR Universal Pigments to your GlassCast 50 resin. This translucent appearance is similar to a stained glass effect and still allows light to pass through the table, enhancing the appearance of depth. CULR pigments are available in a wide range of colours including Indigo Blue for a classic blue river, or Jet Black for a see-through smoked glassed effect.

- Metallic-Effect Powders - Sparkling, brightly coloured metallic effects can be created by adding your choice of metallic SHIMR powders to the resin which is then stirred and agitated to create ripples and swirling patterns.

- Solid Colour Pigments - Opaque, solid colours can be created by adding CULR Universal Pigment to the resin at around 1%. Solid colours, particularly black or white, create bold contrast with the wood and result in more classically elegant furniture.

- Encapsulations - To really put your unique stamp on a river table it is possible to encapsulate just about any objects within the resin, such as pebbles, shells, toys, trainers, badges, even car parts! The only limit is your imagination.

- Glow in the Dark Powders - Photoluminescent powders, often in blue or green but also available in other colours, can be mixed into the resin to create a river that glows in the dark.

Outstanding Technical Support

See the accompanying video tutorials for step-by-step guidance on the successful use of GlassCast 50 for a range of applications, including the classic river table.

For a 'deeper dive', download our Resin River Table Handbook which goes into more detail and covers troubleshooting and alternative methods.

If you still have any questions not covered in the tutorial or guide, just get in touch with our technical team via email, LiveChat or over the phone.

Yes you can layer the resin in that way. The ideal method is to pour the second and any subsequent layers when the first layer has become firm but is still tacky. At this stage no further preparation is needed and you are likely to get an almost invisible join line.

If you need to wait until after the first layer has fully cured, then the resin will need a key with sand paper and a thorough clean before pouring the next layer.

ASK YOUR OWN QUESTION

Customer Product Reviews for Epoxy Resin for River Tables

Perfectly clear, bubble-free resin that produces consistent results. As a premium product, it does suffer with crystallisation, but always returns to water clear after sitting in 60+ degree water for a while. Minimal shrinkage is also a big plus point.

Fantastic product, great at degassing for bubble free castings, good machinability when cutting, turning or shaping/carving.

Great. Super happy. Fast delivery (came next day) and thanks to Charlotte in the office who helped me to find the delivery (at my own house!!

I've been using glass cast 50 since the beginning and have now produced nearly 20 river tables and similar projects. I tested a few other resins in the beginning and settled on glass cast 50 because of the cure speed and bubble free finish. Other resins I tested for river tables were much too slow to cure. One took a week to cure and still felt too soft to machine properly. Great product.

TOP PRODUCT!! have used Glasscast 50 for 3 river tables now, they have all worked perfectly and great technical support from Warren who helped me figure out a problem I was having with tiny air bubbles (was caused by jiffy mixer - dont use one!). Great product, great service.

brilliant product, really happy with the end result, did exactly what it said on the tin. only reason I didn't give 5 stars is because it would have been better if I could buy a 2.5kg kit, the 5 was too big and the 1kg is too small.

No comparisson! Glasscast 50 is the only epoxy resin i will use for my river tables. quality of the product is spot on - bubble free, cures hard, machines great, polishes great. What more can I say? 5 star product.

I have been working with resin for quite a while now, using various resin products, with varied results. After trying GlassCast, I have found a product I'm sticking with. Easy to work with, easy to finish. Night and day from others I have used. Highly recommended.

Highly recommend! Great products supplied via great service. Top quality all round. Will be staying with GlassCast and not even tempted to look elsewhere!

I use a combination of GlassCast 50 for the deep pours I do and GlassCast 3 for finishing and flood coats. I love the products and the service I receive from the team. A score of 5 is not high enough for the quality and service you get from the team!

Fantastic product, great at degassing for bubble free castings, good machinability when cutting, turning or shaping/carving.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Related Products

Related Products

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.