Need any help or advice?+44 (0)1782 450300

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Polypropylene Sheet

Polypropylene plastic sheet is ideal for use as a non-stick baseboard or barriers for your GlassCast epoxy resin projects.

It has a smooth finish and is easy to cut and bond. Use it to create a base or sides for a river table or custom shaped containers for jewellery or wood turning projects.

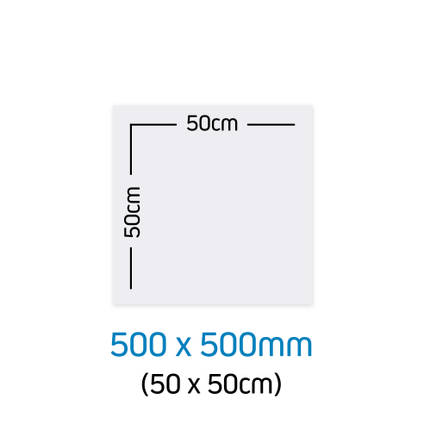

Available in 3 sheet sizes; 500 x 500mm, 1000 x 500mm and 1000 x 1000mm.

PRODUCT VERSIONS

Sheet Size

AVAILABILITY:More than 10 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Polypropylene plastic sheet is ideal for use as a non-stick baseboard or barriers for your GlassCast epoxy resin projects. It has a smooth finish and is easy to cut and bond.

Polypropylene has a smooth finish, is easy to cut and bond and has enough stiffness to help construct sturdy barriers or produce a smooth base. Best of all, epoxy resin does not stick to polypropylene meaning the sheet requires no release agent and can be re-used again and again.

Our polypropylene sheet is 3mm thick and a natural translucent colour. The sheet is available in a range of sizes, please choose the size you require from the drop-down list at the top of the page.

Polypropylene Sheet Recommended Uses

When working with GlassCast epoxy resins, there are many situations where you need to construct barriers or a box to contain the resin whilst it cures. This can be for anything from small-scale jewellery projects through to larger wood turning, or furniture making projects and including of course large pieces like river tables or resin plank tables. In all these situations, it's really helpful to have polypropylene plastic sheet as the perfect smooth, non-stick material to use for the baseboard and sides.

- Baseboard and sidewalls for a river table

- Container for layered 3D resin art

- Custom mould shape for jewellery pieces

- Fitted 'resin bath' container for wood stabilisation

- Custom mould shapes for pen-blanks

Polypropylene Sheet Advantages

- Smooth and shiny finish

- Completely non-stick to epoxy resin

- Can be re-used again and again

- Easy to cut and shape

- Can be heated/bent if required

How to Use

Using polypropylene sheet as a baseboard, barriers or container for your GlassCast resin project could not be easier. Simply cut the sheet into the sizes you need using a hand saw. Where necessary, assemble the parts using a hot-melt glue-gun or some Resin Barrier/Release Tape, both of which allow the container to be dismantled once the resin has cured.

Imperfections

Please note: Polypropylene sheet is manufactured as an industrial material, it is also quite soft and does mark easily. It is not intended to be cosmetically perfect and some light scratches from manufacture or handling should be expected.

If you intend to use the sheet to produce the final finish on your part then some light finishing work will be required.

Polypropylene plastic sheet is ideal for use as a non-stick baseboard or barriers for your GlassCast epoxy resin projects. It has a smooth finish and is easy to cut and bond.

Polypropylene has a smooth finish, is easy to cut and bond and has enough stiffness to help construct sturdy barriers or produce a smooth base. Best of all, epoxy resin does not stick to polypropylene meaning the sheet requires no release agent and can be re-used again and again.

Our polypropylene sheet is 3mm thick and a natural translucent colour. The sheet is available in a range of sizes, please choose the size you require from the drop-down list at the top of the page.

Polypropylene Sheet Recommended Uses

When working with GlassCast epoxy resins, there are many situations where you need to construct barriers or a box to contain the resin whilst it cures. This can be for anything from small-scale jewellery projects through to larger wood turning, or furniture making projects and including of course large pieces like river tables or resin plank tables. In all these situations, it's really helpful to have polypropylene plastic sheet as the perfect smooth, non-stick material to use for the baseboard and sides.

- Baseboard and sidewalls for a river table

- Container for layered 3D resin art

- Custom mould shape for jewellery pieces

- Fitted 'resin bath' container for wood stabilisation

- Custom mould shapes for pen-blanks

Polypropylene Sheet Advantages

- Smooth and shiny finish

- Completely non-stick to epoxy resin

- Can be re-used again and again

- Easy to cut and shape

- Can be heated/bent if required

How to Use

Using polypropylene sheet as a baseboard, barriers or container for your GlassCast resin project could not be easier. Simply cut the sheet into the sizes you need using a hand saw. Where necessary, assemble the parts using a hot-melt glue-gun or some Resin Barrier/Release Tape, both of which allow the container to be dismantled once the resin has cured.

Imperfections

Please note: Polypropylene sheet is manufactured as an industrial material, it is also quite soft and does mark easily. It is not intended to be cosmetically perfect and some light scratches from manufacture or handling should be expected.

If you intend to use the sheet to produce the final finish on your part then some light finishing work will be required.

Any burr left on the edge after cutting can be quickly cleaned-up using a sharp blade dragged sideways along the edge.

You're right that for a short while, we did offer a 2m x 1m sheet size. The reason this sheet is no longer available on our website is because - over recent years - the couriers (TNT, FedEx, UPS, DHL etc.) have been overwhelmed by the amount of freight going through their networks and have really limited the amount of 'unconveyable' freight they will accept. Given the size of the large 2m x 1m sheet, it's almost impossible to find a courier service who is willing to carry such a large product. Whilst the 2m x 1m sheet could be sent on a double pallet, the cost of this is enormous and would be 10 or 20 times the cost of the sheet. Therefore, the answer is simply that it is not viable to ship large sheets of a low cost product like this in the current market.

It would depend on the size of the table. Given enough radius the polypropylene sheet would bend around it fine but if it's a small piece with a tight radius then you might want to look for a thinner sheet. Alternatively, make a barrier using a more flexible material like the Resin Release Tape as the GlassCast resin will not stick to it.

This would depend on the size of the table. For most table sizes a thin strip of polypropylene could easily be bent round to form the outer barrier but but if the table was particularly small then you might need to consider something thinner. Alternatively, you could make a barrier using any flexible material you like and then apply Resin Release Tape to this material to make it non-stick as the GlassCast won't stick to the release tape.

Most glues will not bond well to polypropylene. However, hot melt glues work very well for the temporary bonding of polypropylene sheeting for use as mould boxes and mould flanges.

This polypropylene sheet is semi-translucent. It is a natural white colour which does allow some light to pass through.

ASK YOUR OWN QUESTION

Customer Product Reviews for Polypropylene Sheet

I’ve just used this Polypropylene Sheet for the first time and I have to say it is superb. I’m making 2 resin lamps and did as was suggested using a glue gun to make the moulds. When it came to de moulding the glue came off really easy and the sheet literally just popped off the solid resin when I applied a little bit of pressure! They don’t break either so I can use these pieces again to make the same size moulds. Would definitely recommend.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Customers Also Bought

Customers Also Bought

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.