Need any help or advice?+44 (0)1782 450300

Downloads (2)

This is a chemical product. Before storage or use you must download and read the accompanying safety and technical datasheets.

| Safety Datasheet (SDS) - EN | ||

| Technical Datasheet (TDS) |

Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 50 Epoxy Resin for Pen Blanks - 500g

- GlassCast®

- 4.5/5 Average rating

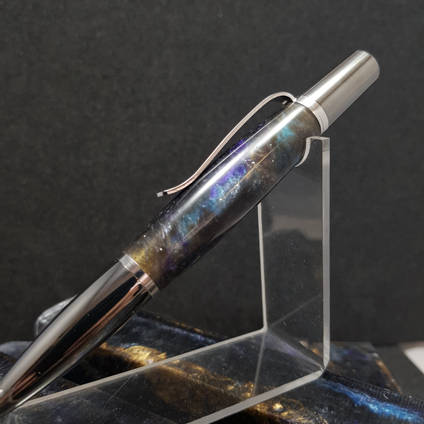

If you’re looking for an easy-to-use, reliable epoxy resin that's ideal for making pen-blanks and other wood turning blanks then you’re in the right place!

The recommended pour thickness for GlassCast 50 is 50mm into a silicone mould and 25mm into a blank containing wood or other encapsulations like fir-cones.

GlassCast 50 is trusted by respected wood-turners and pen-turners around the world for its bubble-free castings, superb machining qualities and easy polishing. GlassCast 50's stable formula is also fully compatible with a wide range of pigments, dyes and metallic effects making it the perfect casting resin for making pen blanks.

Sold as a kit, including resin and hardener. Available in 500g, 1kg and 5kg kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 20 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

The perfect epoxy resin for pen blanks

GlassCast 50 is a firm favourite amongst wood-turners and pen-makers who need a thick section (up to 50mm) casting resin that machines really nicely, cures bubble-free, stabilises and bonds to wood and is compatible with a wide range of pigments, dyes and decorative effects.

Any turners who have worked much with cast resin will know that there’s nothing worse than tiny pits on the surface of your barrel caused by air bubbles trapped within the resin! GlassCast 50 was designed to be self-degassing and to produce bubble-free castings without the need for a pressure-pot or degassing chamber, leaving you with silky smooth turnings that you’ll just want to keep touching!

For those who do want to use either a degassing chamber or pressure-pot to drive resin into wood in order to stabilise it further, there are a number of techniques for using GlassCast 50 in this way.

Why choose GlassCast 50 for making pen blanks?

- Highly machinable – Turns, cuts, and polishes beautifully.

- Self-degassing – Almost zero air entrapment, without degassing.

- Suitable for thick sections – Cast up to 50mm depth in a single pour.*

- Solvent free – 100% solids, no VOCs, almost odourless.

- UV resistant – Best-in-class protection from yellowing.

- Widely compatible – Works great with most pigments, dyes, and effects.

*50mm into a conventional mould, 25mm maximum depth into highly insulating environments like a wooden cavity or enclosure.

Getting Started

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 80 mins | 60 mins | 40 mins |

| Maximum Pour Depth into a thin walled mould (silicone/plastic) | 50mm | 40mm | 30mm |

| Maximum Pour Depth into wood or an insulating mould | 25mm | 25mm | 18mm |

| Initial Cure | 96 hrs | 72 hrs | 48 hrs |

What to cast into

There are a number of options to choose from what it comes to what to cast your pen blanks into.

- Simple batten frame – Timber battens can be wrapped in release film (or even brown parcel tape) and screwed down to a plastic base to make a simple watertight frame or any size.

- Simple plastic frame – Alternatively, strips of polypropylene plastic can be hot-melt glued onto a baseboard to make a simple frame.

- Silicone moulds* – Specialist pen-turning suppliers offer high quality silicone moulds suitable for casting single or multiple resin pen blacks. Better still, some of these moulds allow you to cast the resin ‘tube in’ which means less wasted resin and less work to turn the blank into a finished pen barrel.

- HDPE moulds* – Alternatively, some suppliers offer sturdy HDPE plastic moulds in various sizes. Many of these moulds also offer tube in casting.

* Repeatedly casting epoxies into silicone of HDPE moulds will cause the moulds to degrade. Using Vaseline or similar as a release agent has been found to be very effective at extending the life of both silicone and rigid plastic moulds.

How much resin will I need?

The amount of resin need to cast a pen blank will vary depending on the size of the blank, whether you’re casting tube in and whether you’re adding other materials, such as wood, into the mould.

A typical 180mm x 20mm x 20mm blank, cast without the tube in would need 72g of resin. Casting 'tube in' or around wood will reduce this significantly meaning that a little resin goes a long way.

Adding different colours and effects

The number of ways that GlassCast 50 can be tinted, pigmented or otherwise modified to achieve different appearances is almost limitless. Our own range includes pigments and additives to create translucent tints, vivid opaque colours, and even sparkling metallic effects.

- Translucent tints – Translucent ‘see-through’ colours, like a stained-glass effect, can be achieved by adding just a tiny drop of our CULR universal resin pigments.

- Opaque pigments – Make solid opaque colours by adding a few drops more of the CULR universal pigments.

- Metallic-effect powders – For shimmering, swirling metallic effects, just add a pinch or two of our metallic effect SHIMR powders.

Combining, blending and marbling

Of course, much of the fun is in blending, combing and marbling colours and effects together. This is done by mixing separate pots of different colours and then bring them together in different ways in the mould. For the most dramatic marbling effects, the resin can be allowed to partially ‘gel’ in the pots before being combined and disturbed in the mould.

Inspiration, and help if you need it

Take a look in the GlassCast customer gallery to see beautiful, original pens and blanks created by other talented customers, all using GlassCast clear epoxy resin.

If you have any questions at all, please get in touch through our contact page, social media, Livechat or over the phone. Our friendly team are happy to help.The perfect epoxy resin for pen blanks

GlassCast 50 is a firm favourite amongst wood-turners and pen-makers who need a thick section (up to 50mm) casting resin that machines really nicely, cures bubble-free, stabilises and bonds to wood and is compatible with a wide range of pigments, dyes and decorative effects.

Any turners who have worked much with cast resin will know that there’s nothing worse than tiny pits on the surface of your barrel caused by air bubbles trapped within the resin! GlassCast 50 was designed to be self-degassing and to produce bubble-free castings without the need for a pressure-pot or degassing chamber, leaving you with silky smooth turnings that you’ll just want to keep touching!

For those who do want to use either a degassing chamber or pressure-pot to drive resin into wood in order to stabilise it further, there are a number of techniques for using GlassCast 50 in this way.

Why choose GlassCast 50 for making pen blanks?

- Highly machinable – Turns, cuts, and polishes beautifully.

- Self-degassing – Almost zero air entrapment, without degassing.

- Suitable for thick sections – Cast up to 50mm depth in a single pour.*

- Solvent free – 100% solids, no VOCs, almost odourless.

- UV resistant – Best-in-class protection from yellowing.

- Widely compatible – Works great with most pigments, dyes, and effects.

*50mm into a conventional mould, 25mm maximum depth into highly insulating environments like a wooden cavity or enclosure.

Getting Started

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 80 mins | 60 mins | 40 mins |

| Maximum Pour Depth into a thin walled mould (silicone/plastic) | 50mm | 40mm | 30mm |

| Maximum Pour Depth into wood or an insulating mould | 25mm | 25mm | 18mm |

| Initial Cure | 96 hrs | 72 hrs | 48 hrs |

What to cast into

There are a number of options to choose from what it comes to what to cast your pen blanks into.

- Simple batten frame – Timber battens can be wrapped in release film (or even brown parcel tape) and screwed down to a plastic base to make a simple watertight frame or any size.

- Simple plastic frame – Alternatively, strips of polypropylene plastic can be hot-melt glued onto a baseboard to make a simple frame.

- Silicone moulds* – Specialist pen-turning suppliers offer high quality silicone moulds suitable for casting single or multiple resin pen blacks. Better still, some of these moulds allow you to cast the resin ‘tube in’ which means less wasted resin and less work to turn the blank into a finished pen barrel.

- HDPE moulds* – Alternatively, some suppliers offer sturdy HDPE plastic moulds in various sizes. Many of these moulds also offer tube in casting.

* Repeatedly casting epoxies into silicone of HDPE moulds will cause the moulds to degrade. Using Vaseline or similar as a release agent has been found to be very effective at extending the life of both silicone and rigid plastic moulds.

How much resin will I need?

The amount of resin need to cast a pen blank will vary depending on the size of the blank, whether you’re casting tube in and whether you’re adding other materials, such as wood, into the mould.

A typical 180mm x 20mm x 20mm blank, cast without the tube in would need 72g of resin. Casting 'tube in' or around wood will reduce this significantly meaning that a little resin goes a long way.

Adding different colours and effects

The number of ways that GlassCast 50 can be tinted, pigmented or otherwise modified to achieve different appearances is almost limitless. Our own range includes pigments and additives to create translucent tints, vivid opaque colours, and even sparkling metallic effects.

- Translucent tints – Translucent ‘see-through’ colours, like a stained-glass effect, can be achieved by adding just a tiny drop of our CULR universal resin pigments.

- Opaque pigments – Make solid opaque colours by adding a few drops more of the CULR universal pigments.

- Metallic-effect powders – For shimmering, swirling metallic effects, just add a pinch or two of our metallic effect SHIMR powders.

Combining, blending and marbling

Of course, much of the fun is in blending, combing and marbling colours and effects together. This is done by mixing separate pots of different colours and then bring them together in different ways in the mould. For the most dramatic marbling effects, the resin can be allowed to partially ‘gel’ in the pots before being combined and disturbed in the mould.

Inspiration, and help if you need it

Take a look in the GlassCast customer gallery to see beautiful, original pens and blanks created by other talented customers, all using GlassCast clear epoxy resin.

If you have any questions at all, please get in touch through our contact page, social media, Livechat or over the phone. Our friendly team are happy to help.We would usually recommend allowing the resin to cure for at least 48 hours before trying to machine it. You will find that the resin machines differently as it continues to fully harden over about a 7 day period. Some turners prefer to do the main shaping work quite early in the cure when the resin is softer and cuts more easily (you'll see the swarf coming off in longer, more pliable peels), but for final finishing (sanding and polishing) the harder and more fully cured the resin is the better; it really doesn't polish well at all until it's really hard after 2-3 days.

Allow a minimum of 48 hours to fully harden before machining begins.

ASK YOUR OWN QUESTION

Customer Product Reviews for Epoxy Resin for Pen Blanks

Perfectly clear, bubble-free resin that produces consistent results. As a premium product, it does suffer with crystallisation, but always returns to water clear after sitting in 60+ degree water for a while. Minimal shrinkage is also a big plus point.

Fantastic product, great at degassing for bubble free castings, good machinability when cutting, turning or shaping/carving.

Great. Super happy. Fast delivery (came next day) and thanks to Charlotte in the office who helped me to find the delivery (at my own house!!

I've been using glass cast 50 since the beginning and have now produced nearly 20 river tables and similar projects. I tested a few other resins in the beginning and settled on glass cast 50 because of the cure speed and bubble free finish. Other resins I tested for river tables were much too slow to cure. One took a week to cure and still felt too soft to machine properly. Great product.

TOP PRODUCT!! have used Glasscast 50 for 3 river tables now, they have all worked perfectly and great technical support from Warren who helped me figure out a problem I was having with tiny air bubbles (was caused by jiffy mixer - dont use one!). Great product, great service.

brilliant product, really happy with the end result, did exactly what it said on the tin. only reason I didn't give 5 stars is because it would have been better if I could buy a 2.5kg kit, the 5 was too big and the 1kg is too small.

No comparisson! Glasscast 50 is the only epoxy resin i will use for my river tables. quality of the product is spot on - bubble free, cures hard, machines great, polishes great. What more can I say? 5 star product.

I have been working with resin for quite a while now, using various resin products, with varied results. After trying GlassCast, I have found a product I'm sticking with. Easy to work with, easy to finish. Night and day from others I have used. Highly recommended.

Highly recommend! Great products supplied via great service. Top quality all round. Will be staying with GlassCast and not even tempted to look elsewhere!

Amazing resin and really great to make all kind of projects. I use mainly GlassCast Resin 50 to make custom knife handles, pen blanks, jewellery and all kinds of crafts. The online shop is very intuitive and easy to use. Highly recommended!

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

In the currently selected pack size, this product is classed as dangerous goods in limited quantity for the purposes of transport.

Shipping is possible to all UK addresses, including the Channel Islands, without restriction. However, due to being classed as 'dangerous goods', delivery times are not guaranteed on any delivery service.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

To check availability of shipping to any other country, add the item to your basket and use the shipping calculator on the basket page.

For a full information regarding the shipment of dangerous goods to all destinations, see our delivery information page.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the availability and cost for delivery of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Related Products

Related Products

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.