Need any help or advice?+44 (0)1782 450300

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 3 Epoxy Resin for Agate Coasters - 500g

- GlassCast®

- 5/5 Average rating

If you're interested in creating your own unique resin-art agate coasters and want to use the same resin that’s used by many of the most talented and respected makers out these, then you’re in the right place!

GlassCast 3 is a special clear two-part epoxy coating resin, intended for use up to approximately 5mm thick, which cures with a uniquely smooth, glossy surface - perfect for making beautiful 'agate' style resin art coasters.

Sold as a kit, including resin and hardener. Available in 500g, 1kg and 5kg kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 20 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

The perfect resin for agate style resin-art coasters

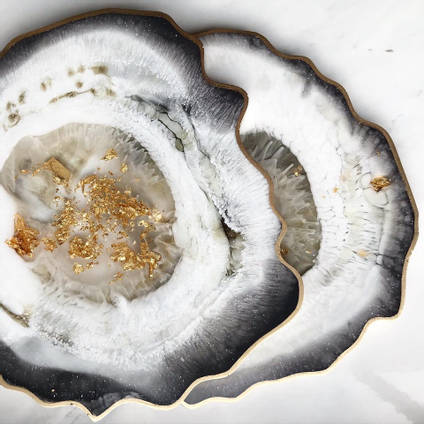

One of the most original and creative forms of resin art that has emerged over the last few years has been the wonderfully diverse world of 'agate' style coaster art, made popular by talented artists such as Luna Art Resin.

These beautiful pieces tend to be cast into specially shaped silicone moulds – often arranged in sets of four – which have an irregular outer edge, echoing the live edges of natural formations like geodes.

The coasters are made by combining, pouring and layering GlassCast 3 epoxy resin with a wide range of pigments, tints, metallic effects and gilding paints to produce distinctive, intricate coaster sets with a perfectly smooth, glossy surface, without the need for polishing.

What makes GlassCast 3 so popular for this type of coasters?

Unlike other types of resin coasters, such as petri-art - made using alcohol inks, and flower preservation, agate-style resin coasters are poured and layered the right way up, with the ‘open face’ of the mould being the top, visible face of the coaster. This makes is extremely important that the resin being used cures with a really smooth, glossy surface finish on its surface.

GlassCast 3 was developed specifically as a coating resin and no other resin has a smoother, glossier surface on its open face. This makes it perfect for agate coasters and is the reason why so many artists choose GlassCast 3 for this type of coaster.

GlassCast 3 advantages for agate-style resin art- Glossy surface finish – GlassCast 3 is a purpose-made coating resin, no other resin has a smoother, glossier surface

- Medium viscosity – Slightly thicker than a casting resin, GlassCast 3 allows colours and effects to be kept in discreet bands

- Ideal cure time – 30mins pot-life allows plenty of working time but pieces can be demoulded in less than 24hrs

- Solvent free – GlassCast 3 is solvent free with almost zero odour

- Self-degassing – No need to degas for bubble-free castings

- Hard wearing – Although resin-art coaster sets are rarely used as day-to-day coasters, GlassCast 3 is incredibly tough and hard-wearing, just in case!

- UV resistant – GlassCast 3 has very good resistance to UV, ensuring your coasters look great for years to come.

Getting Started

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 45 mins | 30 mins | 22 mins |

| Maximum Pour Depth | 9mm | 6mm | 3mm |

| Initial Cure | 36 hrs | 24 hrs | 18 hrs |

What to cast into

- Commercial silicone moulds – As agate style coasters have become more popular, a number of silicone mould manufacturers have started offering basic agate style coaster-set moulds which are now available through various sellers on marketplaces such as Amazon and eBay.

- Artisan moulds from independent makers – A small number of established artists, such as Luna Art Resin, offer their own range of truly unique coaster mould sets. Support your fellow artists and benefit from their skill and craft by using their agate coaster mould sets.

- Improvised moulds – Make your own one-off agate coaster moulds by simply using modelling wax or modelling clay to create an irregular frame on a simple plastic base.

Adding different colours and effects

Well, this is where the fun starts! Make the colour palette for your resin-art by adding a wide range of pigments, tints, metallic effects and even glitters, glow powders to your resin.

- Translucent tints – Translucent 'see-through' colours, like a stained-glass effect, can be achieved by adding just a tiny drop of our CULR universal resin pigments.

- Opaque pigments – Make solid opaque colours by adding a few drops more of the CULR universal pigments.

- Metallic-effect powders – For shimmering, swirling metallic effects, just add a pinch or two of our metallic effect SHIMR powders.

- Gilding paints and gold leaf – Products like 'liquid leaf' and other brilliant gold metallic paints can painted onto the outside edge of the coasters after demoulding to give them a decadent touch. Or, for total extravagance, real gold leaf can be layered into the resin during casting!

Inspiration, and help if you need it

Take a look in the GlassCast customer gallery to see beautiful, original agate resin-art coasters created by other talented customers including Luna Art Resin, Claudio Barrasso Designs and many more, all using GlassCast clear epoxy resin.

If you have any questions at all, please get in touch through our contact page, social media, Livechat or over the phone; our friendly team are hear to make sure you‘re 100% happy and producing beautiful pieces you’re delighted with.

The perfect resin for agate style resin-art coasters

One of the most original and creative forms of resin art that has emerged over the last few years has been the wonderfully diverse world of 'agate' style coaster art, made popular by talented artists such as Luna Art Resin.

These beautiful pieces tend to be cast into specially shaped silicone moulds – often arranged in sets of four – which have an irregular outer edge, echoing the live edges of natural formations like geodes.

The coasters are made by combining, pouring and layering GlassCast 3 epoxy resin with a wide range of pigments, tints, metallic effects and gilding paints to produce distinctive, intricate coaster sets with a perfectly smooth, glossy surface, without the need for polishing.

What makes GlassCast 3 so popular for this type of coasters?

Unlike other types of resin coasters, such as petri-art - made using alcohol inks, and flower preservation, agate-style resin coasters are poured and layered the right way up, with the ‘open face’ of the mould being the top, visible face of the coaster. This makes is extremely important that the resin being used cures with a really smooth, glossy surface finish on its surface.

GlassCast 3 was developed specifically as a coating resin and no other resin has a smoother, glossier surface on its open face. This makes it perfect for agate coasters and is the reason why so many artists choose GlassCast 3 for this type of coaster.

GlassCast 3 advantages for agate-style resin art- Glossy surface finish – GlassCast 3 is a purpose-made coating resin, no other resin has a smoother, glossier surface

- Medium viscosity – Slightly thicker than a casting resin, GlassCast 3 allows colours and effects to be kept in discreet bands

- Ideal cure time – 30mins pot-life allows plenty of working time but pieces can be demoulded in less than 24hrs

- Solvent free – GlassCast 3 is solvent free with almost zero odour

- Self-degassing – No need to degas for bubble-free castings

- Hard wearing – Although resin-art coaster sets are rarely used as day-to-day coasters, GlassCast 3 is incredibly tough and hard-wearing, just in case!

- UV resistant – GlassCast 3 has very good resistance to UV, ensuring your coasters look great for years to come.

Getting Started

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 45 mins | 30 mins | 22 mins |

| Maximum Pour Depth | 9mm | 6mm | 3mm |

| Initial Cure | 36 hrs | 24 hrs | 18 hrs |

What to cast into

- Commercial silicone moulds – As agate style coasters have become more popular, a number of silicone mould manufacturers have started offering basic agate style coaster-set moulds which are now available through various sellers on marketplaces such as Amazon and eBay.

- Artisan moulds from independent makers – A small number of established artists, such as Luna Art Resin, offer their own range of truly unique coaster mould sets. Support your fellow artists and benefit from their skill and craft by using their agate coaster mould sets.

- Improvised moulds – Make your own one-off agate coaster moulds by simply using modelling wax or modelling clay to create an irregular frame on a simple plastic base.

Adding different colours and effects

Well, this is where the fun starts! Make the colour palette for your resin-art by adding a wide range of pigments, tints, metallic effects and even glitters, glow powders to your resin.

- Translucent tints – Translucent 'see-through' colours, like a stained-glass effect, can be achieved by adding just a tiny drop of our CULR universal resin pigments.

- Opaque pigments – Make solid opaque colours by adding a few drops more of the CULR universal pigments.

- Metallic-effect powders – For shimmering, swirling metallic effects, just add a pinch or two of our metallic effect SHIMR powders.

- Gilding paints and gold leaf – Products like 'liquid leaf' and other brilliant gold metallic paints can painted onto the outside edge of the coasters after demoulding to give them a decadent touch. Or, for total extravagance, real gold leaf can be layered into the resin during casting!

Inspiration, and help if you need it

Take a look in the GlassCast customer gallery to see beautiful, original agate resin-art coasters created by other talented customers including Luna Art Resin, Claudio Barrasso Designs and many more, all using GlassCast clear epoxy resin.

If you have any questions at all, please get in touch through our contact page, social media, Livechat or over the phone; our friendly team are hear to make sure you‘re 100% happy and producing beautiful pieces you’re delighted with.

Hi Amy, GlassCast 3 has heat resistance as good as any epoxy resin on the market, including those marketed as 'heat resistant' or 'high temperature'. Having said that, there really are no 'pour and cure' epoxies that cannot be marked by particularly hot objects; trust us - we've tested them all!

GlassCast 3 has been a firm favourite for coasters for many years now and continues to be the #1 choice for most makers, including those making a selling coasters as a business. When it comes to high temperatures, the advice should always be the same: GlassCast 3 has good temperature resistance and, once fully cured, will not be marked by most 'drinkable' temperature hot drinks, however, a very hot 'black coffee', straight from the kettle then placed and left on the coaster could leave a small ring or mark. Over time, these rings or marks generally tend to fade away and if not, they can easily be polished out in the future.

One thing you can do to significantly improve the temperature resistance of your coasters is to fully cure them at elevated temperature. 'Baking' the finished coasters in an oven at 60C will fully cure the GlassCast 3 resin and make it much less likely to mark if very hot objects are placed on it in future.

ASK YOUR OWN QUESTION

Customer Product Reviews for Epoxy Resin for Agate Coasters

I use GlassCast 3 for all my coasters. I make my own free form moulds using silicone and the self-levelling properties in this resin mean that the surface finish is always perfect and I only have to work on the edges.

I follow Luna Art Resin on Instagram and brought GlassCast 3 to create some coasters in Luna's style - it worked perfectly and is my resin of choice!

I love the glossy finish of GlassCast 3 and the affordable price helps to keep my art accessible. For the majority of my work I use GlassCast 3 - like for these Agate Coasters and love it's crystal clear clarity and long working time.

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.