Need any help or advice?+44 (0)1782 450300

Downloads (3)

| GlassCast 3 Safety Datasheet (SDS) - EN | ||

| Technical Datasheet (TDS) | ||

| Resin Penny Floor Handbook |

Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

GlassCast 3 Epoxy Resin for Penny Floors - 5kg

- GlassCast®

- 5/5 Average rating

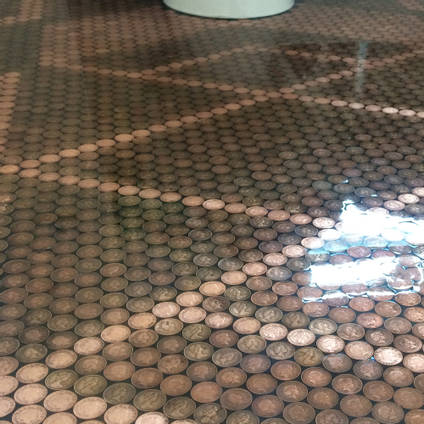

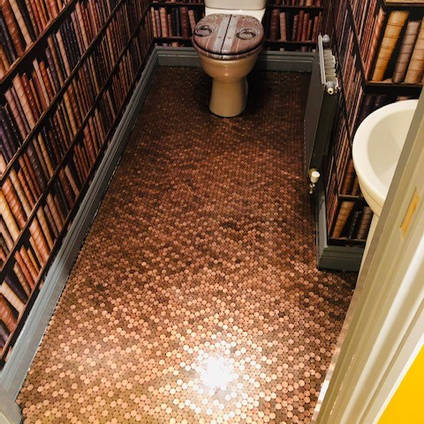

GlassCast 3 Penny Floor Resin is a clear, two-part epoxy resin perfect for creating a super glossy coating over a penny floor or other decorative floor!

Used by thousands of customers around the world to create a beautifully flat, glossy, and hard-wearing resin floor coating for decorative epoxy penny floors. The recommended pour thickness for GlassCast 3 Penny Floor epoxy is 3mm.

Sold as a kit, including resin and hardener. Available in 500g, 1kg, 5kg, 15kg and 30kg kit sizes.

PRODUCT VERSIONS

Kit Size

AVAILABILITY:More than 10 availablefor immediate shipping

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

The perfect epoxy resin for penny floor projects

GlassCast 3 is a premium quality clear epoxy coating resin designed specifically to produce a super-smooth, hard-wearing, high-gloss surface for decorative applications like penny floors. In fact, GlassCast 3 was the resin used in the famous UK Penny Floor Project video which went viral on YouTube with over 100 million views!

This purpose-designed coating resin uses special additives - not found in more general purpose clear epoxy systems – which mean GlassCast 3 cures with a near-perfect smooth, glossy surface which really shows off the look of the pennies (or other decorative inclusions) under the resin.

GlassCast 3 has been developed to be as easy-to-use as possible and is suitable for use by professional installers or DIY users.

Why choose GlassCast 3 for a penny floor?

- Self-levelling – No resin cures with a smoother, glossier surface.

- Self-degassing – Releases trapped air bubbles.

- UV stable – Minimal yellowing.

- Solvent free – 100% solids, no VOCs, almost odourless.

- Hard-wearing – GlassCast is very tough and scratch resistant.

- Most trusted – GlassCast 3 has been used on thousands of floors, worldwide!

Getting Started

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 45 mins | 30 mins | 22 mins |

| Maximum Pour Depth | 9mm | 6mm | 3mm |

| Initial Cure | 36 hrs | 24 hrs | 18 hrs |

How much resin do I need?

Working out how much resin you need for a penny floor is very easy. Start by working out the area of your floor in square metres; this is just the length in metres, multiplied by the width.

So, for example, a 3m x 2m room = 6 square metres.

For grouted pennies multiply the area by 2.5; so 6 sqm x 2.5 = 15kg of resin

For un-grouted pennies multiply the area by 3.5; so 6 x 3.5 = 21kg of resin

What else do I need?

Very little! – Pouring a GlassCast 3 coating over your pennies is straight-forward and requires no special tools or equipment. You’ll just need some nitrile gloves, 2 large mixing buckets, a mixing stick a spreader

.Full instructions and support

If you're interested in creating your own penny floor then we’re here to make the process as simple and reliable as possible:

- Video tutorial – Watch our penny floor tutorial for a complete video guide to the process, from start to finish.

- Resin penny floor handbook – When it comes to resin penny floors, we literally wrote the book! Download our free resin penny floor handbook for an even more detailed guide to the process with extra information like troubleshooting and aftercare.

- Resin calculator – Visit our resin calculator page and click 'Penny Floor' to work out how much resin you need.

- Expert help if you need it – Our friendly team are available by email, LiveChat, telephone and through social media to answer any questions you may have.

Although easy-to-use, GlassCast 3 is still a chemical product. To make sure you work safely and get great results, you must download and read the technical and safety datasheets from this page before you begin.

GlassCast 3 is also the ideal product for applying glossy finish surfaces to bar tops and table tops in addition to penny floors and decorative floors.

The perfect epoxy resin for penny floor projects

GlassCast 3 is a premium quality clear epoxy coating resin designed specifically to produce a super-smooth, hard-wearing, high-gloss surface for decorative applications like penny floors. In fact, GlassCast 3 was the resin used in the famous UK Penny Floor Project video which went viral on YouTube with over 100 million views!

This purpose-designed coating resin uses special additives - not found in more general purpose clear epoxy systems – which mean GlassCast 3 cures with a near-perfect smooth, glossy surface which really shows off the look of the pennies (or other decorative inclusions) under the resin.

GlassCast 3 has been developed to be as easy-to-use as possible and is suitable for use by professional installers or DIY users.

Why choose GlassCast 3 for a penny floor?

- Self-levelling – No resin cures with a smoother, glossier surface.

- Self-degassing – Releases trapped air bubbles.

- UV stable – Minimal yellowing.

- Solvent free – 100% solids, no VOCs, almost odourless.

- Hard-wearing – GlassCast is very tough and scratch resistant.

- Most trusted – GlassCast 3 has been used on thousands of floors, worldwide!

Getting Started

Ambient Temperature, Pot-Life and Pour Depth

The GlassCast range of resins, in common with all epoxies, generate heat as part of the curing process. The amount of time the mixed resin can spend in the pot, as well as the maximum depth it can be poured at, will vary depending on the ambient temperature.

For best results, we recommend working in a consistent room temperature of 18-20°C. GlassCast can be used in temperatures from 15 to 25°C but higher temperatures will reduce the pot-life and the maximum pour-depth of the resin significantly, as shown in the table below.

| Ambient Temperature | 15°C (minimum) | 20°C (minimum) | 25°C (minimum) |

|---|---|---|---|

| Maximum Time in Pot (Pot Life) | 45 mins | 30 mins | 22 mins |

| Maximum Pour Depth | 9mm | 6mm | 3mm |

| Initial Cure | 36 hrs | 24 hrs | 18 hrs |

How much resin do I need?

Working out how much resin you need for a penny floor is very easy. Start by working out the area of your floor in square metres; this is just the length in metres, multiplied by the width.

So, for example, a 3m x 2m room = 6 square metres.

For grouted pennies multiply the area by 2.5; so 6 sqm x 2.5 = 15kg of resin

For un-grouted pennies multiply the area by 3.5; so 6 x 3.5 = 21kg of resin

What else do I need?

Very little! – Pouring a GlassCast 3 coating over your pennies is straight-forward and requires no special tools or equipment. You’ll just need some nitrile gloves, 2 large mixing buckets, a mixing stick a spreader

.Full instructions and support

If you're interested in creating your own penny floor then we’re here to make the process as simple and reliable as possible:

- Video tutorial – Watch our penny floor tutorial for a complete video guide to the process, from start to finish.

- Resin penny floor handbook – When it comes to resin penny floors, we literally wrote the book! Download our free resin penny floor handbook for an even more detailed guide to the process with extra information like troubleshooting and aftercare.

- Resin calculator – Visit our resin calculator page and click 'Penny Floor' to work out how much resin you need.

- Expert help if you need it – Our friendly team are available by email, LiveChat, telephone and through social media to answer any questions you may have.

Although easy-to-use, GlassCast 3 is still a chemical product. To make sure you work safely and get great results, you must download and read the technical and safety datasheets from this page before you begin.

GlassCast 3 is also the ideal product for applying glossy finish surfaces to bar tops and table tops in addition to penny floors and decorative floors.

The amount of resin needed is slightly different depending on if the bottle tops/pennies have been grouted level or not. For Penny Floors we always recommend grouting the floor as it seals the pennies in and helps provide a smoother overall finish to the floor. For other objects such as bottle tops, it may not always be practical to use grout.

If the floor has been grouted, you will need 2kg of resin per square meter coverage. This will give a layer approximately 2mm thick over the bottle tops/pennies.

For un-grouted floors, you will need 3kg of resin per square meter to be covered. Again, this will give a layer approximately 2mm thick over the bottle tops. The extra kilo of resin is to fill all the gaps surrounding the bottle tops.

Grouting between penny's and other embedded items is not necessary and doing so is usually down to personal preference. In terms of which type and brand of grout, any grout is fine although semi-flexible grouts might be preferable if there is any movement in the floor at all.

In all cases, you must ensure that the grout is fully dried before you apply the resin as excess moisture can cause resins to go cloudy and in extreme cases may effect the cure.

You need roughly 2716 one pence coins per square meter of floor. If you go for 2 pence coins instead, 1750 two pence coins are needed for every square metre of area. That is based on them being tightly configured together. Other patterns may need a different amount.

ASK YOUR OWN QUESTION

Customer Product Reviews for Epoxy Resin for Penny Floors

Can’t tell you how pleased I am with my penny floor, great tutorial and very helpful technical support to all my questions over the phone, I was so apprehensive about getting the resin right, as I’ve never done a project like this before, but I mixed and poured the resin today and it looks beautiful like a sheet of glass, thanks for all your help

Worth it. Nervous but worked really well. Has finished the floor project really well. Was surprised as to how warm the floor now feels.

Amazing Stuff! Two penny floors look amazing.

I created the 'UK Penny Floor Project' that went viral using 27,000 pennies and GlassCast! The product and advice is fantastic!

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Shipping Information

Restrictions

This product is not classed as dangerous goods for transport and can be shipped to all destinations without restriction.

Shipping to EU countries is now done through our European subsidiary based in the Netherlands. All EU customers should use www.easycomposites.eu.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the delivery cost of this item to your address, add it to your basket and then use the instant shipping calculator on the basket page.

Related Products

Related Products

100% SECURE

PAYMENT METHODS

GlassCast Resin is a trading name of Easy Composites Ltd, registered in England, 7486797. All content copyright (C) Easy Composites Ltd, 2022. All rights reserved.